A versatile AOI that supports SMT and DIP inspection

Detecting floating parts with laser height measurement

Inline/Desktop type, compatible with L-size boards (650 x 550 mm)

- Tabletop and inline models available, supporting large boards from M to L size

- Z-axis is standard equipment. Even tall parts can be inspected with optimal focus.

- Detects component lift using laser height measurement. Measuring up to 70mm.

- 8-angle camera (optional) allows for actual inspection and oblique inspection

- Establish traceability of inspection results by introducing the CatchSystem (optional)

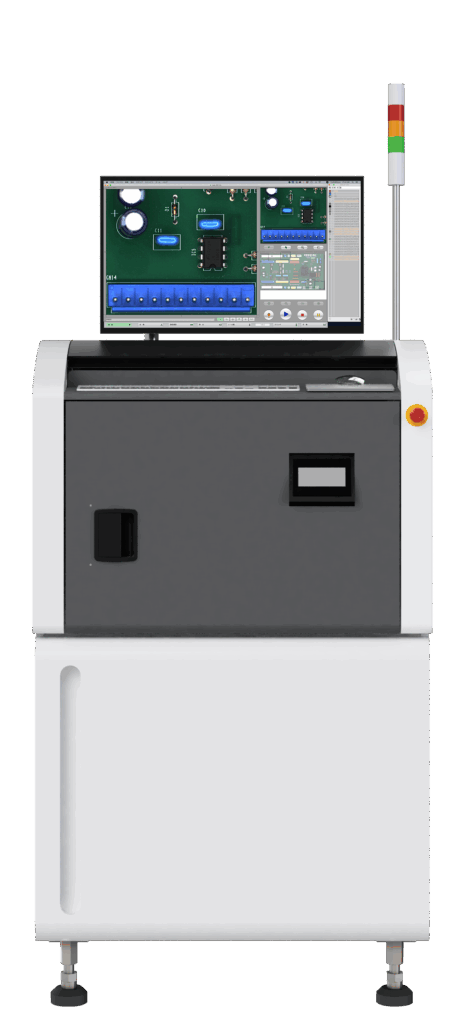

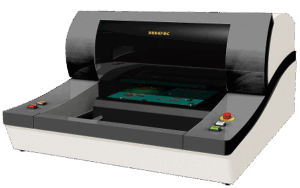

Desktop types

A desktop type that can easily handle small-lot, multi-product inspections.

The installation method is simple and can flexibly accommodate changes to the factory layout.

We also offer a dedicated stand (optional), which can solve the problem of selecting a table.

- Choose from M size (350 x 250 mm) or L size (650 x 550 mm)

- Supports both SMT and DIP inspection

- The M22X achieves high-speed inspection by driving the inspection head and substrate table separately.

- The U22X inspection head moves in the XY direction and does not move the board, making it ideal for inspecting inserted components before flow soldering and for heavy boards.

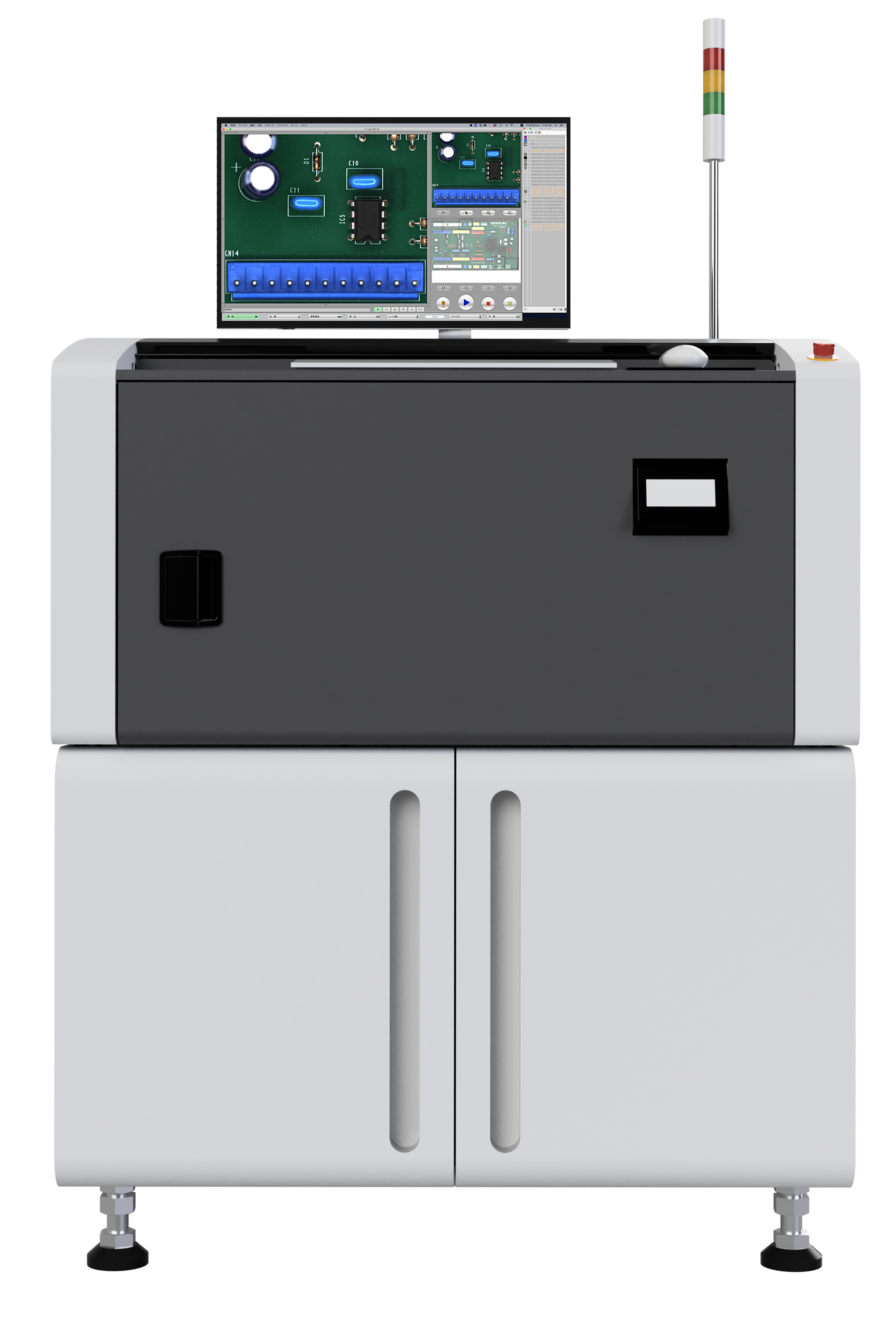

Inline types

It is compatible with pre- and post-reflow and DIP lines, contributing to automation and labor savings.

By utilizing offline teaching (optional), program data can be created and real-time debugging can be performed even during production.

- Choose from M size (350 x 250 mm) or L size (550 x 550 mm)

- Ideal for component inspection before reflow, final inspection after reflow, and inserted component inspection before flow

- Automatic conveyor width adjustment is supported as standard when switching programs

- Supports automatic model switching by reading barcodes

仕様

| Desktop – M22XJ-350H | Desktop – U22XJ-550H | Inline – U22XJ-350LH | Inline – U22XJ-350LH | |

| External dimensions | W736 x D874 x H493 mm | W1000 x D1090 x H607mm | W770 x D846 x H1300 mm | W1070 x D1106 x H1330 mm |

| Body weight | 65 kg | 150 kg | 210 kg | 280 kg |

| Power | AC 100 V – 240 V | AC 100 V – 240 V | AC 100 V – 240 V | AC 100 V – 240 V |

| Implementation Limitations | Top 40 mm Bottom 65 mm | Top 40 mm Bottom 70 mm | Top 40 mm Bottom 30 mm | Top 40 mm Bottom 30 mm |

| Camera | 5M | 5M | 5M | 5M |

| lens | Telecentric lens | Telecentric lens | Telecentric lens | Telecentric lens |

| Field of view | 36 x 30 mm (15μm) | 36 x 30 mm (15μm) | 36 x 30 mm (15μm) | 36 x 30 mm (15μm) |

| Light | DL lighting or ML lighting | DL lighting or ML lighting | DL lighting or ML lighting | DL lighting or ML lighting |

| Inspection range | 350 x 250 mm | 550 x 550 mm | 350 x 250 mm | 550 x 550 mm |

| Angle Camera | OPTION | OPTION | OPTION | OPTION |

| Z-axis stroke | 30 mm | 40 mm | 30 mm | 30 mm |

| Laser height measurement | 〇 | 〇 | 〇 | 〇 |

| Power | 350 W | 350 W | 350 W | 350 W |

| Conveyor Speed | ー | ー | 10 – 500 mm/sec | 10 – 500 mm/sec |

| Inspection time | 0.3 sec/screen | 0.3 sec/screen | 0.3 sec/screen | 0.3 sec/screen |

※Please note that above specification is subject to change without notice.