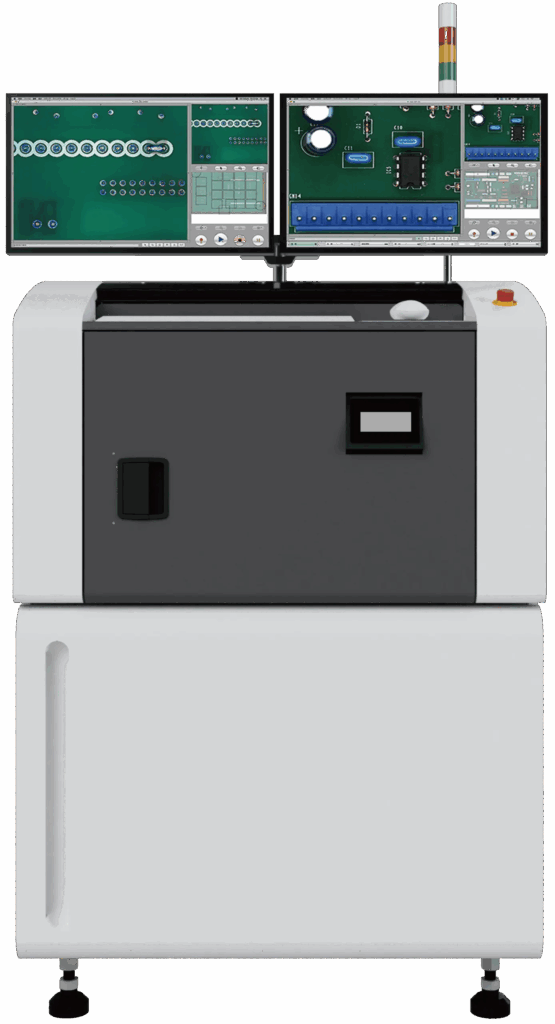

The simultaneous double-sided inspection with independent upper and lower drive is extremely effective in reducing inspection time.

It is ideal for final inspection of not only surface-mounted components but also discrete boards.

- The upper and lower units are equipped with an 8-angle camera and Z axis as standard.

- No need for a turnover machine, consolidating two inspection machines into one contributes to shortening the line length

- Automatic model and width switching by reading product barcodes

- Establish traceability of inspection results by introducing the CatchSystem (optional)

- By simply scanning the barcode on one side of the board, traceability on both sides is possible.

Specification

| Model | D22X-350LH | D22X-550LH |

| External dimensions | W878 x D910 x H1316 mm | W1078 x D1216 x H1329 mm |

| Body weight | 270 kg | 430 kg |

| Power | AC100V – 240V | AC100V – 240V |

| Implementation Limitations | Top:30 mm Bottom:20 mm | Top:30 mm Bottom:20 mm |

| Camera | 5M | 5M |

| Lens | Telecentric lens | Telecentric lens |

| FOV | 36 x 30 mm | 36 x 30 mm |

| Light | DL lighting or ML lighting | DL lighting or ML lighting |

| Inspection range | 350 mm x 250 mm | 550 mm x 550 mm |

| Angle Camera | 〇 | 〇 |

| Z-axis stroke | 〇 | 〇 |

| Laser height measurement | ー | ー |

| Power | 700 W | 700 W |

| Conveyor Speed | 10 – 500 mm/sec | 10 – 500 mm/sec |

| Inspection time | 0.3 sec/画面 | 0.3 sec/画面 |