Supports simultaneous double-sided inspection

UV coating agent (moisture-proof coating agent) and component inspection are integrated into one machine. A rich lineup of 7 models in total supports various coating lines.

- Automating the UV visual inspection environment ensures worker safety.

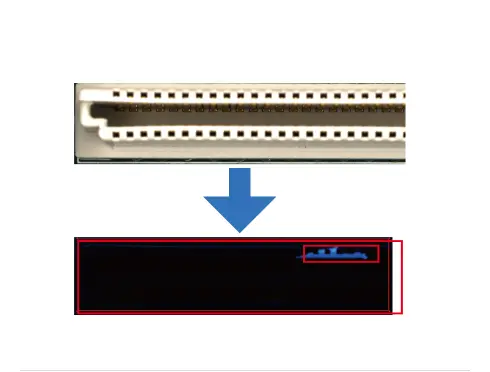

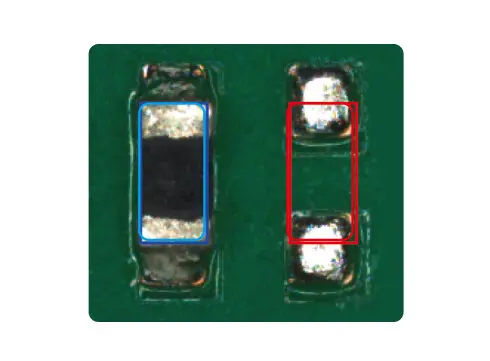

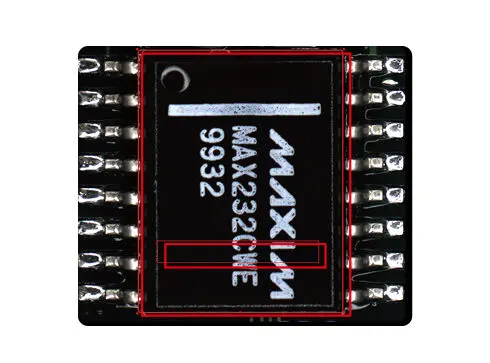

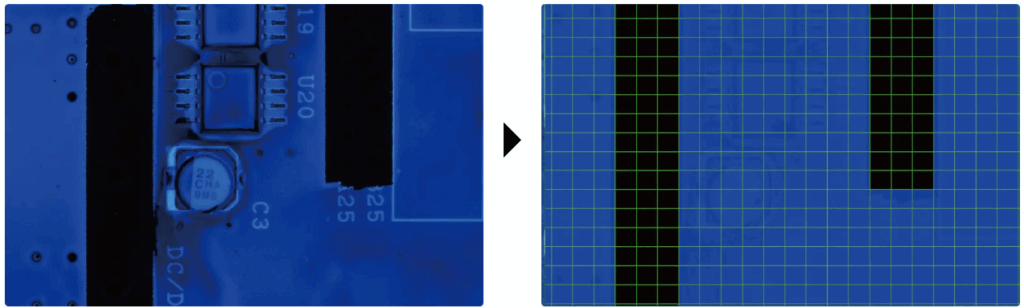

- Detects minute particles that are easily overlooked by visual inspection

- White lighting enables marker and barcode recognition and component inspection

- Equipped with an automatic teaching function for easy data creation

- Equipped with an automatic debugging function for areas of variation during application

- Establish traceability of inspection results by introducing the CatchSystem (optional)

Inspection Examples

Lineup

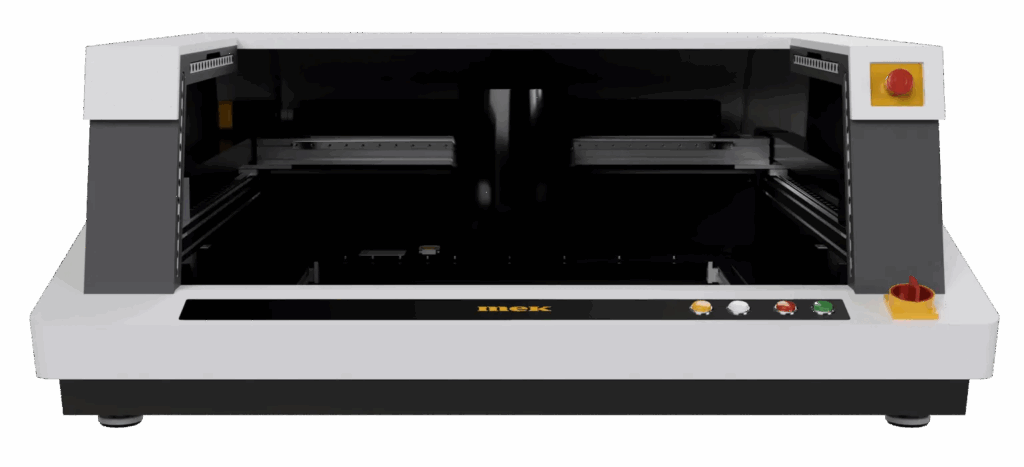

Desktop types

A desktop type that can easily handle small-lot, multi-product inspections.

The installation method is simple and can flexibly accommodate changes to the factory layout.

We also offer a dedicated stand (optional), which can solve the problem of selecting a table.

- Inspection range of L size (520 x 460 mm)

- The inspection head moves in the XY direction and does not move the board, making it ideal for heavy boards.

- An area sensor is installed as standard at the board set entrance to ensure worker safety.

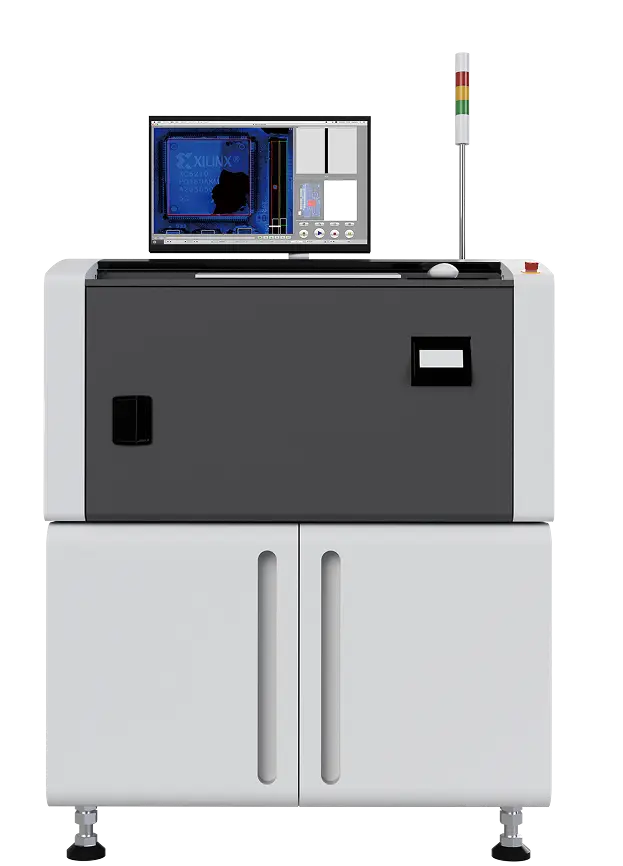

Inline type

By installing it on an automatic coating line and performing all the processes up to inspection, defects are not overlooked and changes in the coating state can be detected early, supporting stable quality.

In the case of simultaneous double-sided inspection, the upper and lower independent drives dramatically reduce takt time. No need for a turnover machine, two inspection machines can be consolidated into one, contributing to shortening the line length.

- For top surface inspection, you can choose from M size (350 x 250 mm) or L size (650 x 550 mm)

- For double-sided simultaneous inspection, you can choose from M size (350 x 250 mm) or L size (550 x 550 mm)

- Automatic conveyor width adjustment is supported as standard when switching programs

- Supports automatic model switching by reading barcodes

Unit types

Depending on the application, the inspection unit can be installed above or below the conveyor, or both.

- Build your own production equipment by incorporating robots into post-transport inspection and conveyors

- Using the input/output I/O, it is possible to issue operation instructions such as starting an inspection, and output OK/NG signals.

Features

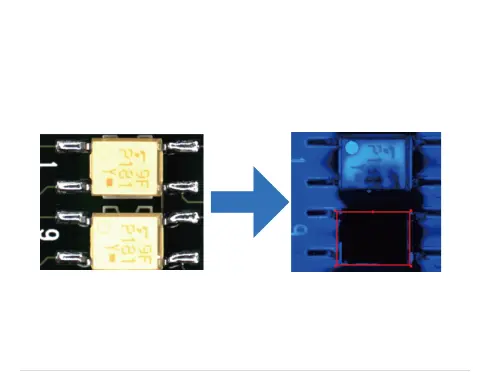

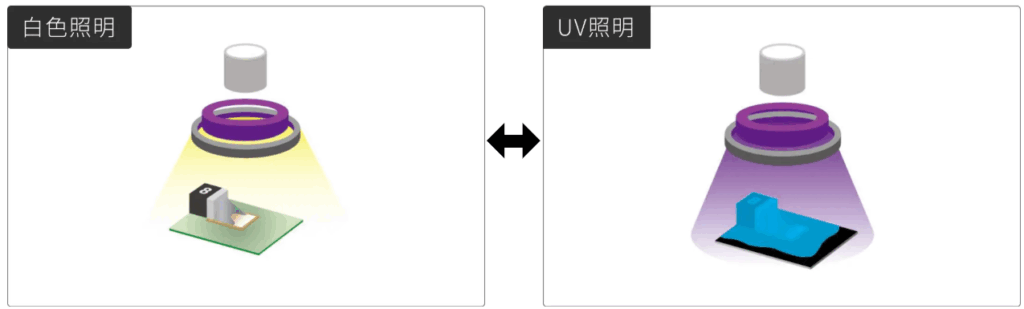

UV coating agent and part inspection all in one machine

White light can be used for component inspection and marker recognition, while UV light can be used for coating inspection.

Inspection can be performed by switching between white light and UV light depending on the object being inspected.

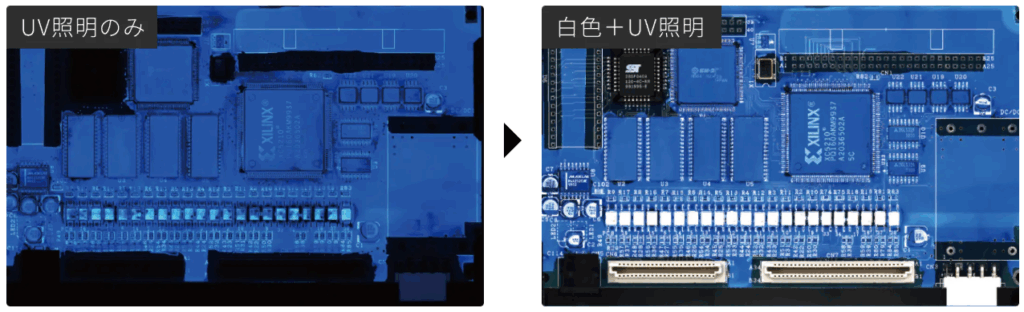

Panoramic image for easy recognition of parts and application areas

By irradiating with UV light and white light simultaneously, images can be captured that make it easy to recognize areas other than those coated and components.

Equipped with automatic teaching function

Data can be easily created by simply scanning a good substrate. The pass criteria can be automatically adjusted with one click to correct for variations in coating.

仕様

| V22XUV-350L | V22XUV-650L | D22XUV-350L | D22XUV-550L | V22XUV-520 | T22XUV-350 | T22XUV-550 | |

| External dimensions | W698 x D800 x H1298mm | W1070 x D1167 x H1328mm | W888 x D880 x H1312mm | W1088 x D1202 x H1331mm | W1030 x D1060 x H410mm | W700 x D880 x H316mm | W770 x D846 x H1300mm |

|---|---|---|---|---|---|---|---|

| Body weight | 210 kg | 240 kg | 260 kg | 400 kg | 95 kg | 50 kg | 210 kg |

| Power | AC 100V~240V | AC 100V~240V | AC 100V – 240V | AC 100V – 240V | AC 100V – 240V | AC 100V – 240V | AC 100V – 240V |

| Applicable board size | Min: 50×50

Max: 350×250 | Min: 50×50

Max: 650×550 | Min: 50×50

Max: 350×250 | Min: 50×50

Max: 520×460 | Min: 50×50

Max: 520×460 | Max: 350×260 | Max: 550×460 |

| Board Weight | 1 kg | 1 kg | 2 kg | 2 kg | 2 kg | ー | ー |

| Implementation Limitations | Top: 60mm

Bottom: 60mm | Top: 60mm

Bottom: 35mm | Top surface 60 mm Bottom surface 35 mm | Top surface 60 mm Bottom surface 70 mm | Top surface 60 mm Bottom surface 70 mm | Inspection surface 60 mm | Inspection surface 60 mm |

| Camera | 5M | 5M | 5M | 5M | 5M | 5M | 5M |

| lens | 5 Macro Lens 19μm | 5 Macro Lens 19μm | Macro lens 19㎛ | Macro lens 19㎛ | Macro lens 19㎛ | Macro lens 19㎛ | Macro lens 19㎛ |

| Field of view | 46 × 38 mm | 46 × 38 mm | 48 × 38 mm | 48 × 38 mm | 48 × 38 mm | 48 × 38 mm | 48 × 38 mm |

| Light | White lighting + UV lighting | White lighting + UV lighting | White + UV lighting | White + UV lighting | White + UV lighting | White + UV lighting | White + UV lighting |

| Z-axis stroke | (I.e. | OPTION | 〇 | 〇 | 〇 | 〇 | 〇 |

| Power | 350 W | 350 W | 700 W | 350 W | 350 W | 350 W | 350 W |

| Conveyor Speed | 10 – 500 mm/sec | 10 – 500 mm/sec | 10-500 mm/sec | ー | ー | ー | ー |

| power | Servo Motor x3 | 3kServo Motor x 3 | Servo Motor x 6 | Servo Motor x 3 | Servo Motor x 3 | Servo Motor x 3 | Servo Motor x 3 |

| Maximum movement speed XY | 720 mm / sec | 720mm / sec | 720 mm / sec | 720 mm / sec | 720 mm / sec | 720 mm / sec | 720 mm / sec |

| Board fixing method | Board outline clamping type | Board outline clamping type | Board outline holding type | Board outline holding type | Board outline holding type | ー | ー |

| Inspection target board thickness | 0.6~2.0mm | 0.6~2.0mm | Mini: 0.6 mm and up | Mini: 0.6 mm and up | Mini: 0.6 mm and up | ー | ー |

| Automatic shutter | OPTION | OPTION | 〇 | ー | ー | ー | ー |

| Target parts | SMT components, insertion components | SMT components, insertion components | ー | ー | ー | ー | ー |

Option

We offer options to help you get the most out of your inspection operations.

Please use this to reduce man-hours and improve quality.

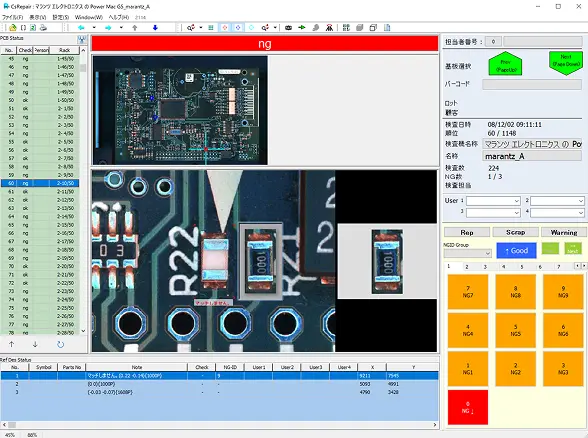

CatchSystem

The results obtained from the inspection are saved in a database and can be checked using images. By aggregating and analyzing the accumulated data, it is possible to understand the operating status of each device, reduce defects, and improve production quality.

The Catch System collects all information from inspection equipment and establishes traceability in production management.

* Separate Windows PC required

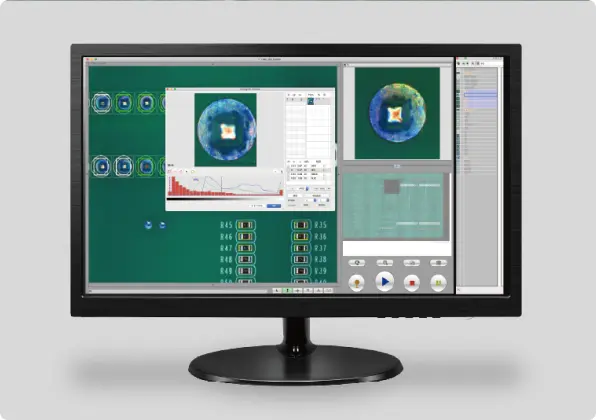

Offline Teaching

Inspection data can be created without stopping the inspection equipment. Inspection data can be created offline on the same screen as the inspection equipment.

Immediately after inspection, defective images are automatically saved, allowing debugging work to be performed on the OLT (not applicable to the X02W).

It can also be used for in-house training purposes.

*A separate PC equivalent to the inspection machine is required.