PCB Cleaners(Inline Type)

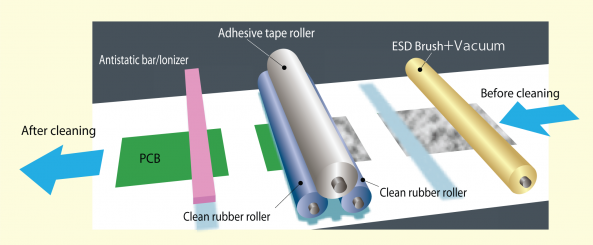

UC-250M-CV takes all the features of the UC-250M, and adds a dual cleaning feature using a combination of a brush roller with the silicone/adhesive cleaning rollers.

Features

- The combination dual dust removal system assures better results than a single brush or adhesive roller system.

- Can set multiple forward and reverse conveyor modes.

- Multiple auto passes ensures more effective micro-dust removal.

- Use the touch panel to select the operation modes (turn ON/OFF brush or rollers).

Specifications (UC-250M-CV)

| Cleaning Side | Top-Side |

|---|---|

| Cleaning Method | Silicone Rollers & Brush-Type |

| Rollers | 2 Silicone 1 Adhesive Tape Roller |

| PCB Size | W: 50 ~ 250mm L: 100 ~ 330mm T: 0.5 ~ 2.0 mm |

| Conveyor Height | 900mm ± 25mm |

| PCB Flow Direction | R -> L or L -> R |

| Conveyor Fixed Side | Front or Rear |

| Conveyor Width Adjustment | Manual (standard) Auto (optional) |

| Conveyor Speed | Adjustable 0 ~ 9 m/min. |

| Ionizer | Internal w/ air blower |

| PCB Anti-Warp | Inside of conveyor |

| PCB Anti-Warp Adjustment | Manual |

| PCB Counter | 0 ~ 9999, Warning Buzzer, Signal Tower |

| Power Supply | AC 100-120V 50/60Hz 300VA |

| Brush Unit | Rotating brush & Vacuum |

| Air Supply | Dry Compressed Air 0.5Mpa |

| Options | – Auto Conveyor Width Adjustment. – 3 Color Signal Tower. – Custom Paint. – Large PCB System(400mm PCB width) – X Large PCB System(460mm PCB width) – Top & Bottom Cleaning System. |

* Specifications subject to change without notice.