高性价比机型 YK-XE

通过自动化解决人员短缺的烦恼!

以合适的价格实现生产现场的高效率、省人力、稳定品质。

- 机械臂长度:400mm~710mm

- 最大搬运重量:4kg~10kg

特長

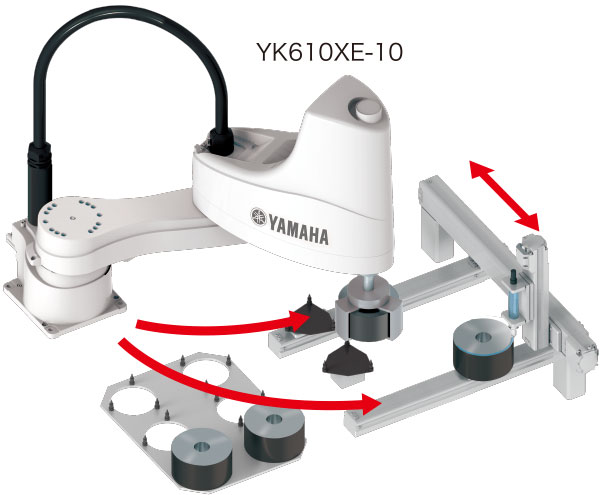

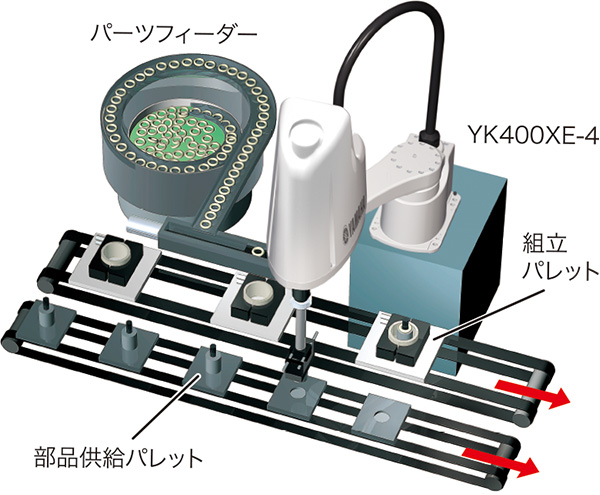

01 适用于汽车零部件等的搬运、组装

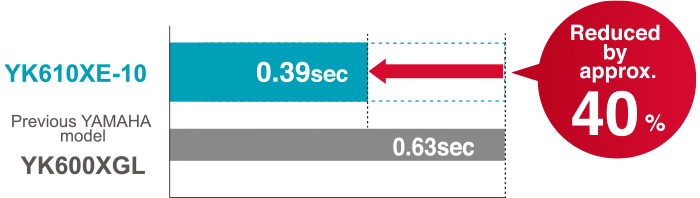

02 通过高速动作提高生产效率

通过改善机械臂结构,减轻振动和优化运动,从而缩短了标准周期时间。高速且振动较少的敏捷动作,有利于提高生产效率。

03 用途广泛,最大可搬运重量 4kg~10kg

支持领域广泛,如需要高精度的组装作业、需要高速动作的食品等的分类作业等。最大可搬运重量为10kg,还可支持汽车零部件等有一定重量的工件。

04 使用示例

05 高性价比

Cost performance(性价比)高。

能够以合适的价格实现生产现场的高效率、省人力、稳定品质。

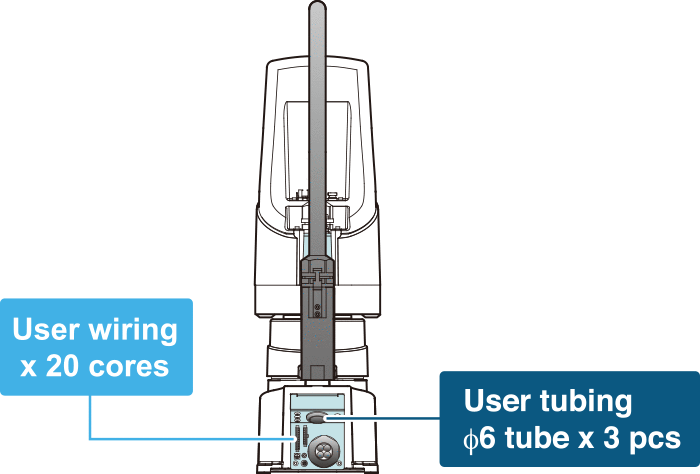

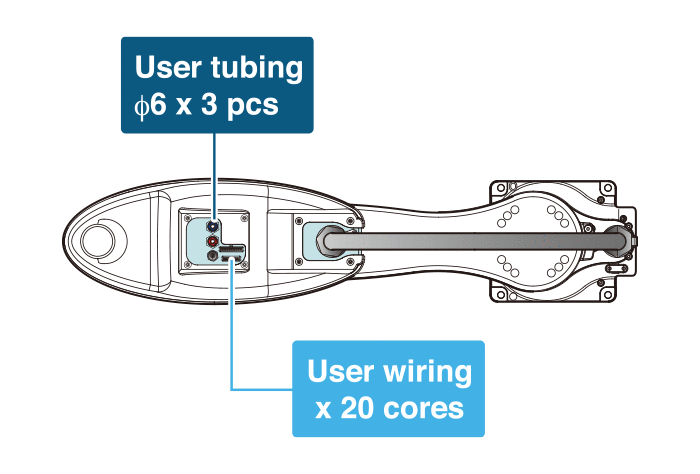

06 适用性提高

可用于工具用途的接线和配管的数量、粗细为同等级别产品中的较高水平。简化布线和布管,降低断线的风险。(YK510XE-10、YK610XE-10、YK710XE-10)

and the User tubing φ4 x 3 pcs.

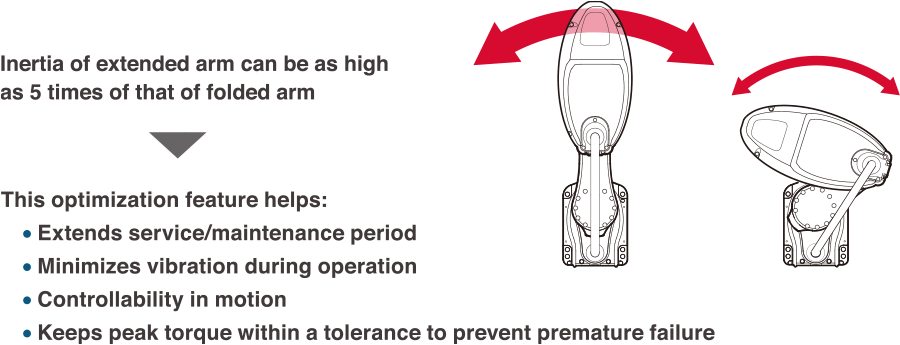

07 自动设定合适的加减速

可以根据动作开始时机械臂的姿态和动作结束时机械臂的姿态,自动匹配加速度,减速度。

只需输入3个参数※,马达最大转矩和减速器允许最大转矩就不会超出允许值。

不论何时都可以发挥马达的最大功率,保持高加减速。

※搬运重量、R轴惯性力矩、R轴惯性力矩偏移量

08 选择中通轴、中通盖 (选配规格)YK400XE-4也支持

可选择便于处理气路和配线的配线及配管用“中通轴”、“中通盖”。

无需设计、制作配线及配管安装用锁紧片等,还可轻松探讨配线及配管的路径。

另外,通过穿过本体内部,减轻了对动作时断线的担心。

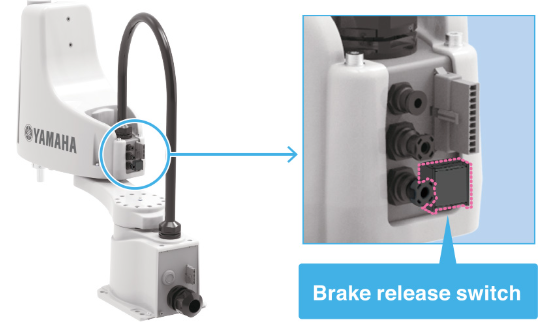

09 可选择制动器解除开关(选配规格)

在紧急停止状态下按下“制动器解除开关”期间,可解除Z轴制动器,使Z轴上下移动(放开开关时,对Z轴施加制动)。调整设置时增强方便性。

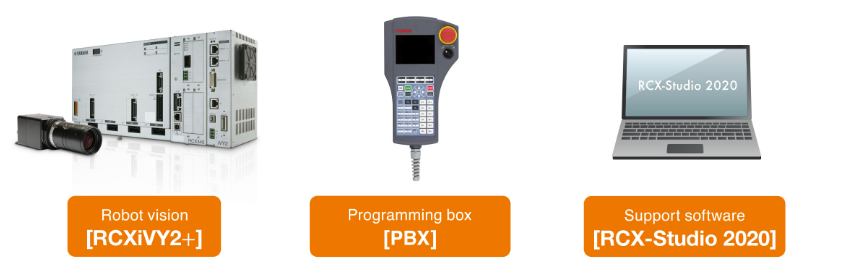

10 与RCX340控制器组合,便于使用

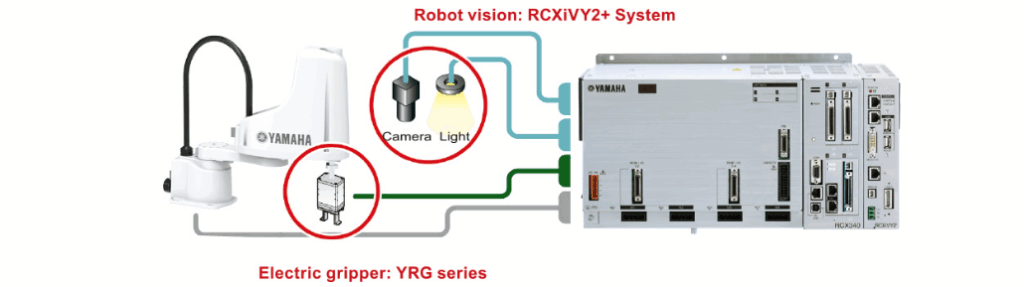

与多功能控制器RCX340配套组合,可以支持多种多样的应用。

使用机器人一体型视觉系统“RCXiVY2+”,可方便地添加图像处理功能,构建高水平的生产设备。

辅助软件和手持编程器等辅助控制工具也非常丰富。

11 还可方便地添加视觉系统

不论是机器人、夹爪还是照明仅需一个控制器即可统一控制。

12 支持多种多样的现场网络

支持CC-Link、EtherNet/IP、DeviceNet、PROFIBUS、PROFINET、EtherCAT等丰富的现场网络。

13 水平多关节机器人从1976年开始积累的良好业绩值得您信赖

雅马哈公司为了在自己的摩托车生产线上使用而开始研发水平多关节机器人。

从1976年雅马哈的工厂引进以来,已有很长的历史积累※。 在市场中锻炼、反复改进而实现的长久业绩是雅马哈获得客户信赖的保证。

※从1984年开始销售

基本仕様

| YK-XE400-4 | X-axis | Y-axis | Z-axis | R-axis | ||

|---|---|---|---|---|---|---|

| Axis specifi cations | Arm length(mm) | 225 | 175 | 150 | – | |

| Rotation angle(°) | ±132 | ±150 | – | ±360 | ||

| AC servo motor output(W) | 200 | 100 | 100 | 100 | ||

| Deceleration mechanism | Transmission method | Motor to speed reducer | Direct-coupled | Timing belt | ||

| Speed reducer to output | Direct-coupled | Timing belt | ||||

| Repeatability Note 1(XYZ:mm)(R:°) | ±0.01 | ±0.01 | ±0.01 | |||

| Maximum speed(XYZ:m/sec)(R:°/sec) | 6 | 1.1 | 2600 | |||

| Maximum payload(kg) | 4 kg (Standard specifi cation), 3 kg (Option specifi cations Note 4) | |||||

| Standard cycle time: with 2kg payload Note 2(sec) | 0.41 | |||||

| R-axis tolerable moment of inertia Note 3(kgm2) | 0.05 (0.5kgfcms2) | |||||

| User wiring(sq×wires) | 0.2 × 10 | |||||

| User tubing (Outer diameter) | φ4×3 | |||||

| Travel limit | 1.Soft limit 2.Mechanical stopper (X,Y,Z axis) | |||||

| Robot cable length(m) | Standard: 3.5 m Option: 5 m, 10 m | |||||

| Weight(kg) | 17 | |||||

Note 1.This is the value at a constant ambient temperature. (X,Y axes)

Note 2.When reciprocating 300mm in horizontal and 25mm in vertical directions and performing the coarse positioning arch operation.

Note 3.The acceleration coefficient is set automatically in accordance with the tip weight and offset amount for R-axis moment of inertia settings.

Note 4.Maximum payload of option specifications (with user wiring/tubing through spline type) is 3kg.

| YK510XE-10 | X-axis | Y-axis | Z-axis | R-axis | ||

|---|---|---|---|---|---|---|

| Axis specifi cations | Arm length(mm) | 235 | 275 | 200 | – | |

| Rotation angle(°) | ±134 | ±152 | – | ±360 | ||

| AC servo motor output(W) | 400 | 200 | 200 | 200 | ||

| Deceleration mechanism | Transmission method | Motor to speed reducer | Direct-coupled | Timing belt | ||

| Speed reducer to output | Direct-coupled | Timing belt | ||||

| Repeatability Note 1(XYZ:mm)(R:°) | ±0.01 | ±0.01 | ±0.01 | |||

| Maximum speed(XYZ:m/sec)(R:°/sec) | 7.8 | 2 | 2600 | |||

| Maximum payload(kg) | 10 kg (Standard specifi cation), 9 kg (Option specifi cations Note 4) | |||||

| Standard cycle time: with 2kg payload Note 2(sec) | 0.38 | |||||

| R-axis tolerable moment of inertia Note 3(kgm2) | 0.3 | |||||

| User wiring(sq×wires) | 0.2 × 20 | |||||

| User tubing (Outer diameter) | φ6×3 | |||||

| Travel limit | 1.Soft limit 2.Mechanical stopper (X,Y,Z axis) | |||||

| Robot cable length(m) | Standard: 3.5 m Option: 5 m, 10 m | |||||

| Weight(kg) | 25 | |||||

Note 1.This is the value at a constant ambient temperature. (X,Y axes)

Note 2.When reciprocating 300mm in horizontal and 25mm in vertical directions and performing the coarse positioning arch operation.

Note 3.The acceleration coefficient is set automatically in accordance with the tip weight and offset amount for R-axis moment of inertia settings.

Note 4.Maximum payload of option specifications (with user wiring/tubing through spline type) is 3kg.

| YK610XE-10 | X-axis | Y-axis | Z-axis | R-axis | ||

|---|---|---|---|---|---|---|

| Axis specifi cations | Arm length(mm) | 335 | 275 | 200 | – | |

| Rotation angle(°) | ±134 | ±152 | – | ±360 | ||

| AC servo motor output(W) | 400 | 200 | 200 | 200 | ||

| Deceleration mechanism | Transmission method | Motor to speed reducer | Direct-coupled | Timing belt | ||

| Speed reducer to output | Direct-coupled | Timing belt | ||||

| Repeatability Note 1(XYZ:mm)(R:°) | ±0.01 | ±0.01 | ±0.01 | |||

| Maximum speed(XYZ:m/sec)(R:°/sec) | 8.6 | 2 | 2600 | |||

| Maximum payload(kg) | 10 kg (Standard specifi cation), 9 kg (Option specifi cations Note 4) | |||||

| Standard cycle time: with 2kg payload Note 2(sec) | 0.39 | |||||

| R-axis tolerable moment of inertia Note 3(kgm2) | 0.3 | |||||

| User wiring(sq×wires) | 0.2 × 20 | |||||

| User tubing (Outer diameter) | φ6×3 | |||||

| Travel limit | 1.Soft limit 2.Mechanical stopper (X,Y,Z axis) | |||||

| Robot cable length(m) | Standard: 3.5 m Option: 5 m, 10 m | |||||

| Weight(kg) | 25 | |||||

Note 1.This is the value at a constant ambient temperature. (X,Y axes)

Note 2.When reciprocating 300mm in horizontal and 25mm in vertical directions and performing the coarse positioning arch operation.

Note 3.The acceleration coefficient is set automatically in accordance with the tip weight and offset amount for R-axis moment of inertia settings.

Note 4.Maximum payload of option specifications (with user wiring/tubing through spline type) is 9kg.

| YK710XE-10 | X-axis | Y-axis | Z-axis | R-axis | ||

|---|---|---|---|---|---|---|

| Axis specifi cations | Arm length(mm) | 435 | 275 | 200 | – | |

| Rotation angle(°) | ±134 | ±152 | – | ±360 | ||

| AC servo motor output(W) | 400 | 200 | 200 | 200 | ||

| Deceleration mechanism | Transmission method | Motor to speed reducer | Direct-coupled | Timing belt | ||

| Speed reducer to output | Direct-coupled | Timing belt | ||||

| Repeatability Note 1(XYZ:mm)(R:°) | ±0.02 | ±0.01 | ±0.01 | |||

| Maximum speed(XYZ:m/sec)(R:°/sec) | 9.5 | 2 | 2600 | |||

| Maximum payload(kg) | 10 kg (Standard specifi cation), 9 kg (Option specifi cations Note 4) | |||||

| Standard cycle time: with 2kg payload Note 2(sec) | 0.42 | |||||

| R-axis tolerable moment of inertia Note 3(kgm2) | 0.3 | |||||

| User wiring(sq×wires) | 0.2 × 20 | |||||

| User tubing (Outer diameter) | φ6×3 | |||||

| Travel limit | 1.Soft limit 2.Mechanical stopper (X,Y,Z axis) | |||||

| Robot cable length(m) | Standard: 3.5 m Option: 5 m, 10 m | |||||

| Weight(kg) | 26 | |||||

Note 1.This is the value at a constant ambient temperature. (X,Y axes)

Note 2.When reciprocating 300mm in horizontal and 25mm in vertical directions and performing the coarse positioning arch operation.

Note 3.The acceleration coefficient is set automatically in accordance with the tip weight and offset amount for R-axis moment of inertia settings.

Note 4.Maximum payload of option specifications (with user wiring/tubing through spline type) is 9kg.