“图像检测设备引进很困难”——常见的误解

自动化和IT即使现在,在高度进化的阶段,在生产现场总是需要人类的帮助有些工序是机器人无法完成的,只能由人类来完成。没有办法人为错误发生。成本和宝贵的人力资源利用率从这个角度来看目视检查需要改进的地方尽管我知道,测试设备昂贵,无需担心复杂的设置沒有人可以做這件事。

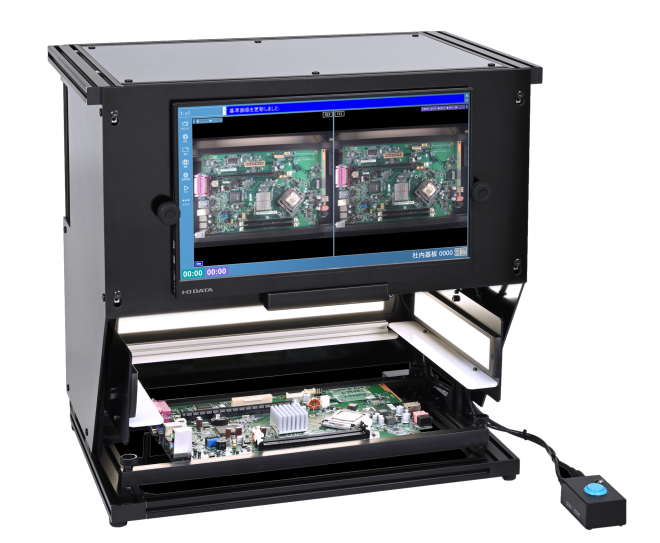

AZVision 是高性能相机和专有软件组合为了简化这个问题它会得到解决的。检查设置是不是部分地,所需面积只需指定。轻松修复模糊形状和它还可以处理位置不同的物体。“直线经理可以很好地利用它”它是在考虑系统的情况下开发的。

特点

- 无移动轴。单次拍摄3秒的快速节拍时间

– 只需一个按钮即可轻松操作

– 可以从前到后进行多次拍摄检查。 - 使用条形码一键切换型号。

- 只需简单设置,10分钟即可开始检测。

- 图像可保存至服务器等任意位置。

- 可测量已完成批次数量和作业节拍时间。

- 通过读取印在电路板上的QR/DM,实现完美的可追溯性。

規格

| AZVision Specifications | ||||||||

|---|---|---|---|---|---|---|---|---|

| Device model name | WV-AZV Zero | WV-AZV GX2 | WV-AZV GH2 | WV-AZV GV2 | ||||

| S | D | S | D | S | D | |||

| Test subject | Compatible board size | Depth 50mm-250mm Width-330mm Board thickness 0.4mm-3.0mm | ||||||

| Main inspection items | Minimum detection size: 1mm (X), 0.5mm (Y) Maximum height: 80mm Maximum number of parts: Unlimited | |||||||

| Parts present or absent, polarity, misalignment, wrong parts, different colors, etc. | ||||||||

| – | – | Solder bridge, unsoldered | Moisture-proofing agent application inspection | |||||

| optical system | camera | 5/20MP USB3.0 CMOS Camera | 20MP USB3.0 CMOS Camera | |||||

| Number of cameras installed | – | 1 | 2 | 1 | 2 | 1 | 2 | |

| Lens focal length | 5 megapixels 20 megapixels | 6mm 12mm | 8mm 16mm | 6mm 12mm | 8mm 16mm | 6mm 12mm | 8mm 16mm | |

| optical resolution | – | 70μm | 57μm | 70μm | 57μm | 70μm | 57μm | |

| Inspection time required | Within 5 seconds/shot (varies depending on inspection area and mesh size) | |||||||

| illumination | – | High brightness white LED 2 directions | High brightness white LED 4 directions | High brightness white LED 2 directions UV-LED 365nm wavelength 2 directions | ||||

| Control PC | CPU: Intel Core-i5/AMD Ryzen5 Memory: 8Gbytes OS: Windows11 | |||||||

| monitor | – | Select 23inch monitor / 15.6inch mobile monitor | ||||||

| power supply | AC 100V 50/60Hz(J) | |||||||

| Operating Temperature Range | Ambient temperature: 0 to +35°C Ambient humidity: 20 to 80% RH (no condensation) | |||||||

| Equipment size | – | 540mm (width), 336mm (depth), 528mm (height) Main unit weight: Approx. 17kg | ||||||

| In-line machine Equipment name | GH2-D-CV | GV2-D-CV |

|---|---|---|

| Inspection items | Component side: Presence, orientation, type, floating of inserted parts, etc. Solder side: No solder, bridges, solder balls, etc. | Missing application of moisture-proof coating area Spattering onto moisture-proof coating area |

| Minimum detection size | Part: 1.0mm x 0.5mm (depends on shooting conditions) Solder ball: φ0.5mm (depends on shooting conditions) | Coating leak: 1mm x 1mm Spatter: 0.2mm x 0.2mm |

| Inspection function | Mesh tool, Color tool, Barcode tool | |

| camera | 2x 20MP resolution USB3.0 camera | |

| lens | 16mm focal length manual focus lens | |

| optical resolution | Approximately 57μm | |

| Inspection time required | 3 seconds to 20 seconds (varies depending on number of shots) Excluding transport time | 5 seconds to 30 seconds (varies depending on number of shots) Excluding transport time |

| illumination | High brightness white flat LED x 4 | High brightness white flat LED x 2, 365nm UV-LED x 2 |

| Control PC | OS: Windows 11 Memory: 8GB | |

| monitor | 23-inch Full-HD monitor (with monitor arm) | |

| power supply | AC 100V | |

| Operating environment | Ambient temperature 0-35°C Ambient humidity 20-80%RH | |

| Device dimensions | Width: 600mm (excluding conveyor overhang) Depth: 730mm Height: 1438mm Weight: Approx. 200kg | |